He won the excellence award at the French WorldSkills event in 2023 and will represent France on the world stage at the event in September 2024: Sacha Greneche, a BTS student in Conception des processus de réalisation de produits (process design in manufacturing) in Lisieux, will champion Normandy milling expertise. Let’s hear multiple perspectives about a trade fuelled by passion and precision with Julien Renault, his mentor at Techma, part of the Link’alia in the Orne area.

Can you tell us more about the job? What does it involve?

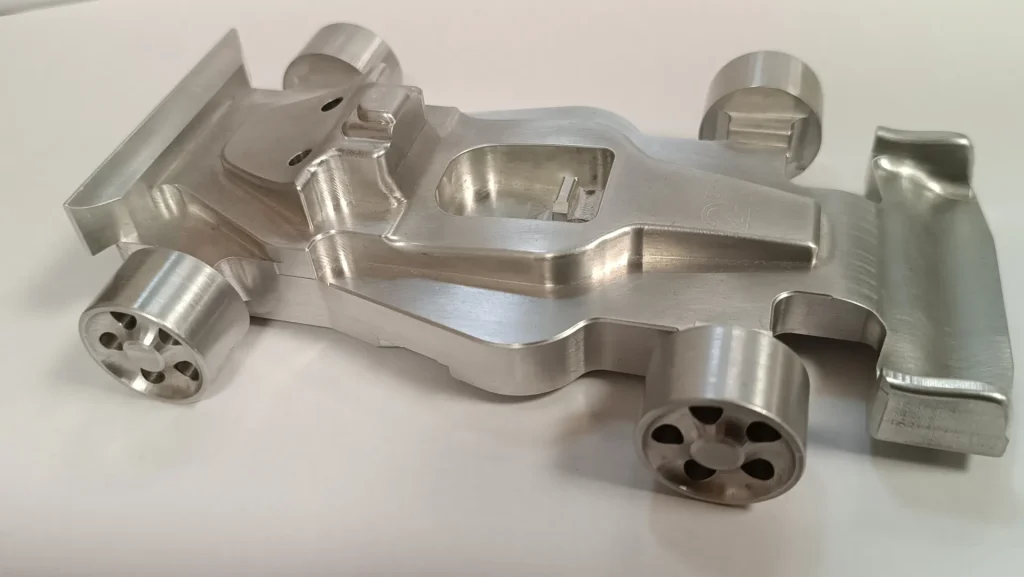

Sacha Greneche: Basically, our job involves making precision pieces by breaking down bulk materials. We create a working drawing on a computer before making the piece on a computer numerical control machine.

Julien: I’m now in charge of the workshop Sacha works in. We mainly fulfil maintenance needs, whether it be mechanical or industrial, in several fields… We also work in the food industry; we do a bit of everything!

What do you like about your job?

Julien: Nowadays, I like managing people, training them and fulfilling their needs, giving them answers and advice. I’m also the middle man and connect management with the workshop. When I started out, what I liked about machining itself is starting from raw material and turning it into something useful.

Sacha Greneche: That’s exactly what I like about it: you start with a problem, specifications, a plan and you make pieces or a collection of pieces to provide a solution. And you do it on your own.

Which qualities do you have to have to work in this job?

Sacha Greneche: You have to be thorough and precise in everything you do.

Julien: Yes, exactly. You need to be good at maths, enjoy DIY and have some common sense.

People don't know much about the world of industry, whether they're young or old. It's a shame because they're exciting careers with roles to fill in the future.

How do you think the job will change in the future?

Julien: It’s constantly changing: it started out with traditional machinery where you had to turn levers and now we use digital and computer programming. 5-axis machining is also a popular topic – currently it’s 3-axis machining – to simplify and update our work. Long-term, 3D printing may be on a wider scale than it is today.

Sacha Greneche: Plus all the brands we work with for equipment and supplies are changing at a rate of knots. That means more possibilities with new and more fine-tuned machines. Julien mentioned 3D printing but there’s also automation, for example, robotic arms for production lines. That’s happening more and more.

It will only get harder to find qualified staff in a few years – it's already happening – but I still believe it has a future.

How was the test at the national competition? How did you train for the international contest?

Sacha Greneche: It was an amazing experience and very rewarding although you don’t realise when it’s happening… thousands of people watching, the clock ticking… It’s exciting and a great challenge I’d recommend to anyone!

Julien: We were all delighted to support Sacha. We’re also giving him lots of time to train and prep for the next competition. We see him as a source of pride, our flagbearer: he’s representing Techma and showing the world what we can do and what we can teach future generations. We let him do his BTS course in 3 years so he could give the competition his all. When he’s here, we’re here to advise and guide him.

Sacha Greneche: I’m training at the moment. It’s tough but a real motivator. The college or French team oversee all my training. I give it my all but it doesn’t feel like work.

I always try to slip it into the conversation that I'm from the best region in France when I talk to the WorldSkills journalists!

What do you think sets Normandy apart?

Sacha Greneche: Normandy is a big draw for our trade because of how diverse the industries here are. For example, the ArianeGroup in Vernon needs machined parts for aerospace; we work in the port and shipbuilding industry in the seaside towns of Cherbourg and Le Havre; there’s a fantastic industrial sector in nearby Flers too. The advantage is that there are lots of different businesses that all have different requirements and work in different industries. That means we have a broader range of expertise.

Julien: We are a hotbed for industry; Forvia and Normand’Innov are driving forces near Flers. Plus I’m 100% Norman, I was born in Flers and have always lived there. I’ve very attached to the Orne area. It’s a very central region, we’re not too far from the capital or from the sea…

How would you persuade young people to explore the trade?

Sacha Greneche: What I tend to say to young people I meet, especially at WorldSkills, is that they should look into the careers in the industry. Lots of people have the wrong idea about the sector. If you’re looking for work, there are jobs to be filled and require expertise. There’s a future in it and it’s not underpaid. It’s a respectable industry: you can start at the bottom and work your way up the ranks in 10 years to be a workshop manager, salesperson or even open your own business.

Julien: A graduate who’s finished their vocational diploma can expect to earn 1600-1700 Euros after tax working 39 hours a week when they start out. That goes up to 2500 after tax after a few years in the same workshop.

Thematics