Published on 03 June 2024

Reading time: 3 min.

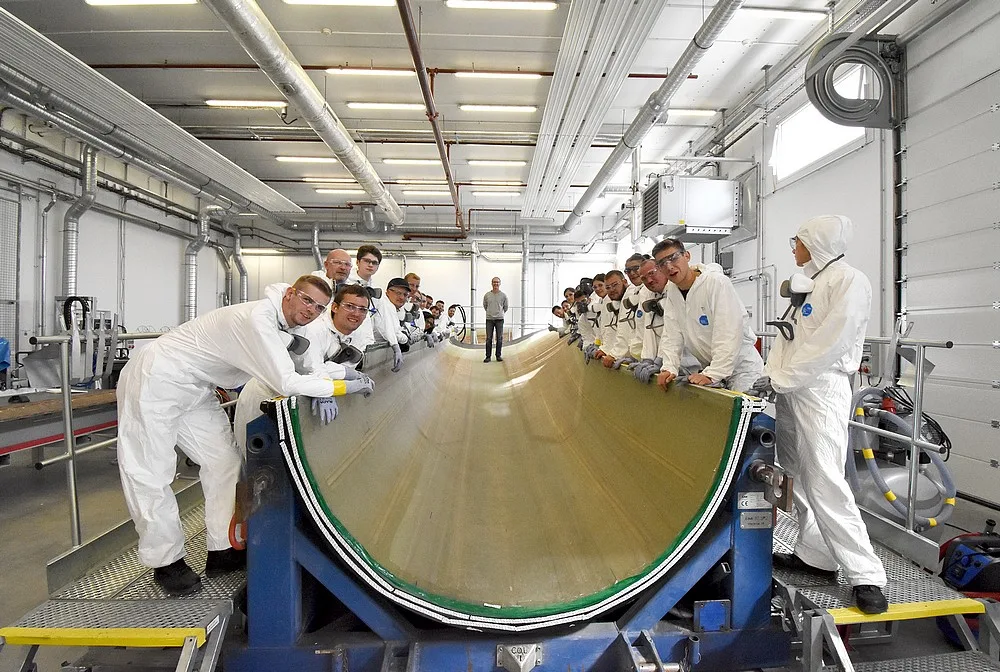

A record-breaking 107m long rotor blade makes it the biggest offshore turbine blade ever built. LM WIND POWER in Cherbourg holds the record. The challenge began in 2017 and has stayed the course: one of the biggest French factories in the General Electric group hasn’t stopped hiring staff since it opened in January 2019.

THE WORLD’S BIGGEST ROTOR BLADE

One in five wind turbines are fitted with a rotor blade made in factories owned by the Danish company LM WIND POWER, part of General Electric. The group decided to open its only factory making giant turbine blades in Cherbourg in 2017. Cherbourg has become a showcase for crafting this global innovation.

The Cherbourg site is the only LM Wind Power site in France and the only one in the world to make 107m blades. The town is in the perfect place for the European offshore wind power market as it has direct access to the docks, making it ideal for our wind turbines that can only be transported by boat.

FLORENCE MARTINEZ FLORES – HDR LM WIND POWER CHERBOURG

These huge rotor blades fit the Haliade X 12 MW designed by GE Renewable Energy. Its turbine is made in Saint-Nazaire. The 260m high wind turbine is the most powerful in the world and can produce enough green energy for 16,000 households.

It’s also the first time that the prototypes have been made in the same factory that will sell them and not at the pilot plant in Denmark. It’s a real feat of technology and ingenuity.

MORE AFFORDABLE GREEN ENERGY

It’s a risk but it’s worth it. 3 prototype blades were fitted onto the Haliade X in Rotterdam in November 2019. It achieved record-breaking results within weeks, producing up to 262kw/h in 24 hours.

It's a huge leap in the wind farm and renewable energy sector that will make green energy more affordable and available.

After beginning the initial marketing phase, GE Renewable Energy was named the main supplier for two American offshore wind farms as well as the world’s biggest wind farm: Dogger Bank off the Yorkshire coast. The factory plans to make over 1200 blades with these contracts.

We're so proud to have watched the site expand and flourish in the space of a year! We went from 0 to 120 employees then 120 to 320 in year 2. It really is an incredible project.

NEW TRADE; NEW BLADE

To pull off the challenge, they had to start from scratch and adapt techniques to make game-changing giant blades. So that meant creating new jobs. The LM Wind Power group focused on skill transfer by assigning experienced operators from its European sites to share their knowledge. The factory also has its own “center of excellence” to train French staff.

The factory now employs over 300 people (including 34% women) from 22 different nationalities. And the company isn’t stopping there: it plans to hire up to 250 new members of staff this summer to stay on track with production and orders.

GOOD TO KNOW

Good news for the planet: competition is fierce in the renewable energy market… Siemens-Gamesa, the main competitor and market leader which also has sites in Normandy, has just announced it’s working on an even more powerful 14MW wind turbine with 108m blades that will be available in 2024. Green energy innovations are getting bigger and better.

Thematics

Did you find this content useful?

Thank you

Thank you for taking the time to let us know that you found this content useful. Your encouragement is important to us, and your feedback helps us to improve.

Thank you

Thank you for taking the time to let us know that this content was not useful to you. We apologise for any inconvenience.

Share this content

Share this content

You might also like

- Caen

- Calvados

- Energie

- Innovation

- International

GANIL, a leading research facility for nuclear physics

Published on 26 May 2025

Reading time: 5 min.

- Choose Normandy for

- Doing business

- Energie

- Environment

TELED, the Normandy method to adapt companies to energy variability

Published on 06 Jan 2025

Reading time: 5 min.

- Cherbourg

- Green Normandy

- International

- Manche

- Maritime & freight industry

Jérémie Morizet and Clément Schapman set a deep-sea exploration record

Published on 06 Jan 2025

Reading time: 9 min.

- Green Normandy

- Industry

- Innovation

- International

- News

Normandy’s manufacturing industry is committed to the future

Published on 10 Dec 2024

Reading time: 2 min.

- Energie

- Fécamp

- Innovation

- Seine-Maritime

- Study

Campus Normandie Eolien: a unique training venue

Published on 10 Dec 2024

Reading time: 5 min.

- Aeronautics & Space industry

- Defense & security

- Green Normandy

- Innovation

- Le Havre

Safran Nacelles clears decarbonisation for take-off near Le Havre

Published on 03 Dec 2024

Reading time: 4 min.

- Event

- Gastronomy

- International

- Network news

- News

World Calvados Day 2024, the third of its kind!

Published on 29 Nov 2024

Reading time: 4 min.

- Fécamp

- Food industry

- Food processing

- Gastronomy

- International

Published on 29 Nov 2024

Reading time: 5 min.